Talking of comfort for a 38-meter Benetti sounds obvious. But as technology advances restlessly, there’s always space to raise the bar.

There’s no arrival point: in this case, we have the demonstration with the partnership between two iconic brands: Benetti and Rolls Royce. What have the two compaines done to increase comfort in navigation and decrease running costs? The former developed the D2P (Displacement to Planing) hull, adopted on the Vivace 125, the latter created the Azipull Carbon, i.e. a carbon fiber transmission (2800 Kg) with pulling propeller, exclusively made for Benetti.

The result is a semi-displacing yacht capable of cruising at speeds in excess of 24 knots with no vibration, or engine noise.

Watch out: this is not a press release, but my personal report after a sea trial in Viareggio on board Iron Man, the first unit of Vivace 125 (another four are under construction and a fifth one is ready for delivery): vibration and noise are almost non-existent at any speed, even when turning sharp. Here’s a video to demonstrate it all (turn up the volume):

http://www.boatmag.it/upload/2016/06/Benetti-Video-Cabina-di-Pilotaggio.m4v

First of all the Rolls-Royce pods allowed to move the engines to the far back of the vessel, far from the cabins. Then, the peculiar semi-displacing hull (Benetti patent) can cruise at 16-18 knots with the engines running at 50%. The usual displacing hulls, which are normally rounded towards the aft, and the planing ones which are much sharper, require more power from the engines. In the first case the engines are smaller and need full steam to reach 12-14 knots, in the second one the power itself is required to keep the hull above the waterline.

So, how’s the D2P Benetti hull made? The transom is shaped like two gullwings from where two long tunnels start and go along the length up to the bow, where a flat and sharp bulb works as a wave-pierce (and virtually stretches the waterline), rather than reduce the water drag as a usual rounded bulb. Beside the physics, there’s the construction technology, with carbon fiber reducing the weight by 40%.

Watch the wavepierce bulb in action

http://www.boatmag.it/upload/2016/06/Benetti-Video-Bulbo-Wavepiercing.m4v

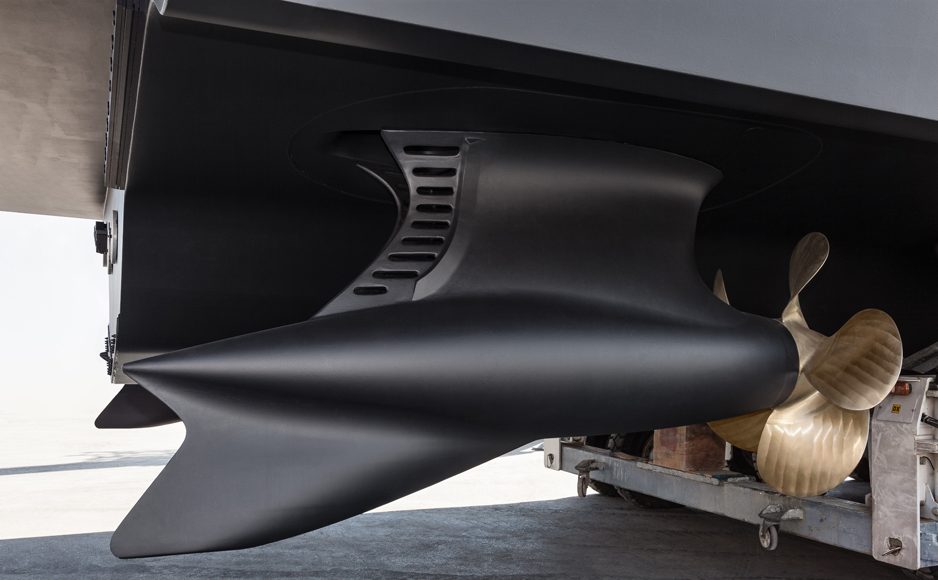

Rolls-Royce Azipull Carbon

Talking of composites, the new pods from Rolls-Royce are largely made in carbon fiber, for a dry weight of just 2800 Kg, split into 1150 on-board and 1650 underwater (including the screw). The latter is then reduced to around 660 Kg, as the thrust in the water reckons 990 Kg.

Rolls-Royce Azipull Carbon are designed mainly for fast yachts, and they are exclusively mounted on Benetti leisure yachts while they find other applications on ferries and working vessels.

The underwater unit is hydrodynamically optimized and includes the bearings, the cone, spiral gears on their mounts, the sealed shaft, and the fixed-pitch pulling propeller. The on-board part consists of the flange to install the engine on the hull, the conic spiral gear, and the hydraulic mechanism to maneuver the waterjet, with patented bearings.

The engine is controlled via a hydraulic system, and managed using an automated system based on modular components by Rolls-Royce Marine, while the transmission is delivered through a series of conic gears installed inside a support case which ensures a high load capability in every working condition.

Follow Us

1251 Fans