Try and imagine if we didn’t have a way to use the sea as a source for fresh water (read: if we didn’t have desalinators): much more space aboard yachts would be dedicated to tanks, with the related weight. We would say goodbye to performance, fuel efficiency, and space on board.

We all know how much the boat’s displacement needs to be met, whether it’s a motorboat or, even more, a sailing vessel, where the only propulsion is the wind.

Here comes the desalinator to rescue us, but first and foremost designers and builders who can then ensure an adequate supply of water without altering the ratio between weight and size of the boat. Secondly it’s the boaters who, through this small machine, can have a virtually unlimited water supply. And forget the tedious water savings that are normally required to the crew.

Careful though: if weight and volume are the problems related to water tanks, in the case of the desalinators the issue is energy consumption. A high power absorption can be a discomfort even on board superyachts with their big generators. Add to this the problem of noise and vibration which, depending on several variables, can be minimal but become annoying. In short, as in any situation, there is two conflicting aspects. What to do then?

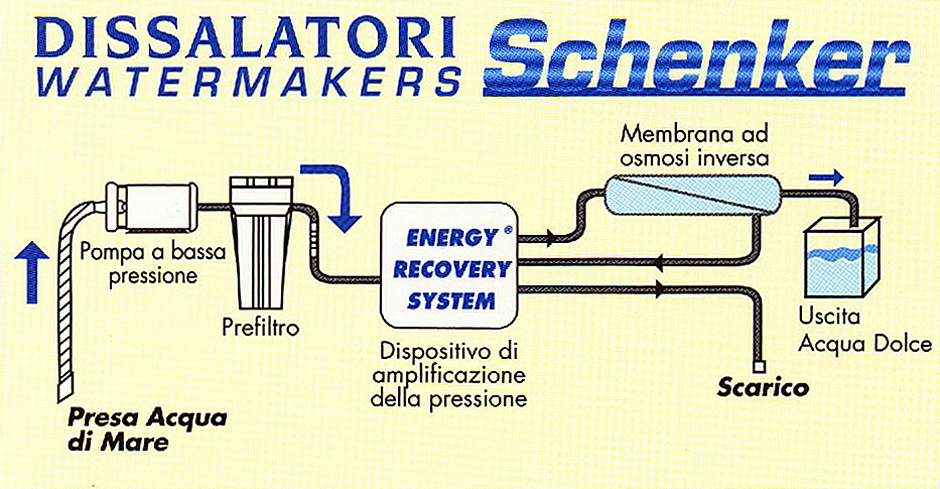

The solution is to

use a low pressure

water intake pump

and amplify its power…

… so energy-consumption, noisy and vibration are drastically reduced. It’s a target achieved by Schenker Watermakers, one of the leading companies in seawater filtration and treatment systems, who has designed an energy recovery system in an eco-sustainable solution, convenientely named…Energy Recovery System. It’s based on the simplicity of operation and reliability, and the first testimonial of this efficiency is one of the greatest sailormen of our time: Giovanni Soldini, on board his state-of-the-art Maserati trimaran.

What is the innovative Energy Recovery System device

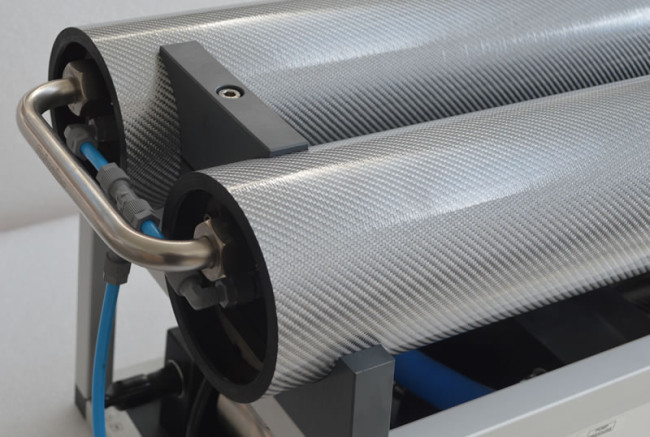

As an alternative to high pressure pumps used for the traditional desalination operation, this system amplifies the power of a normal low pressure pump (installed upstream of the device) and fully retrieves the return hydraulic energy from reverse osmosis membranes. This type of low pressure pump also has the advantage of making the desalinator operation extremely quiet, with total absence of vibration. The water, driven by the low pressure pump, through the prefilters, is then conveyed to the heart of the system, consisting of carbon cylinders inside which concentric pistons of different diameter compress the liquid to high pressure, allowing the phenomenon called ‘reverse osmosis’ and therefore the production of fresh water, which is then stored in the tanks at disposal of on-board crew.

The desalinator

doesn’t collect

any residual salt

within: it is conveyed

outboard through

a sort of exhaust flow

The desalinator’s compartments in contact with salt water are almost entirely made of carbon fiber or acetalic resins, and are virtually free from corrosion. In addition, as Energy Recovery System has been specifically designed for nautical applications, it’s made with materials that are completely immune to brackish water.

Moving parts are minimized thanks to the patented solution that eliminates the need for pilot valves. All the potentially wear-prone components such as O-rings and traditional hydraulic seals have been dropped, while sealing and sliding elements are made up of innovative nano-technology shoes. Such materials feature an abrasion resistance fifteen times higher than steel.

During tests for yield and electrical consumption, energy savings of up to 80% were measured

The Energy Recovery System allows a very high power efficiency. According to Schenker’s data, electrical consumption can drop by 80% compared to traditional desalinators, considering that the average consumption of a Schenker desalinator with this technology is only 4 watts per liter of freshwater produced (for instance, producing 60 liters per hour of fresh water requires only 240 Watts of electricity). The normal power supply from the alternator is therefore largely sufficient to reintegrate the energy consumed, excluding the need to use the generator set. It is therefore possible to install the watermaker on board so that it is fed directly from the batteries, even in the absence of the generator set.

Medium-large Schenker models are also available with 230 volt power supply. Even in this case, reduced electric consumption still allows the use of smaller gen-sets, with an immediate saving of money and a considerable environmental benefit.

Who is Schenker Watermakers

Investments in research and development in the first nearly 20 years of activity of this company, which despite the name is Italian and based in Naples, have led to the creation of three patents from which different, evolved systems have come, such as the energy recovery desalinators. Schenker Watermakers have also recently obtained the ISO 9001: 2015 certification from the Bureau Veritas international certification body.

The simplicity of use with the digital panel on the dashboard

The use of Schenker desalinators is extremely simple, because no manual adjustment is required on the device. Each model is equipped with automatic pressure calibration and all functions are carried out remotely by an easy-to-understand electronic panel that can be installed on the dashboard or belowdecks. Through this board it’s possible to carry out normal operations and a series of evolved activities such as on/off switch, timing, activation of the energy saving function, automatic/periodic/intensive washing, automatic start-up and assisted maintenance.

Three different lines, depending on the type of installation

Schenker makes three different product lines depending on the specific installation requirements and the size of the boat on which the desalinator is to be installed:

Smart: cheap, lightweight and essential ideal for small boats

Ready: with power pump located inside the machine

Modular: with a wide range of flow rate, to cover also the needs of professional boats and superyachts

Modular 60 Digital: fresh water in economy, with remote control

Nowadays, with the implementation of new features, the Schenker Modular 60 Digital desalinator is ideal for medium-sized boats, even if they don’t have a gen-set in the engine room.

It is a lightweight, compact and silent machine, and also features the “Energy Recovery System” patent.

Modular 60 is based on the new technology with sealing elements and moving parts’ slots (shafts, valves, etc.) made up of innovative sliding pads made with nanotechnologies, which have replaced the components most prone to wear such as O-rings and traditional hydraulic seals.

The desalinator, which produces 60 liter per hour with a consumption of just 240 watts, sports new advanced features and digital control via the remote panel described above. It is available with 12/24 volt power, both directly from the batteries or at 230 V, and has a 3-year warranty.

Development and technology are tested also through racing: Schenker is aboard Maserati with Giovanni Soldini

The technical collaboration between Schenker and Giovanni Soldini continues, now with a desalinating machine on board the new Maserati trimaran, specifically designed and built to suit extreme operating conditions.

The device is derived from the “Smart 30 Basic” model but has been made much lighter than the commercial version. The product, which has some of its peculiar qualities in its compactness and ease of operation, is entirely made of carbon fiber and weighs only 18 kg: according to Schenker it’s the lightest desalinator ever built in this category.

Given the peculiar installation, special arrangements have been studied to allow the desalinator to operate correctly at any speed regime. The system will then be able to absorb the stresses due to the planing of the boat at sustained speed on ocean waves.

The next-generation Schenker desalinator transforms seawater into pure fresh water using only a small amount of electricity. On board Maserati it will provide drinking water and water to rehydrate dried food to an average crew of 6-7 people.

Follow Us

1251 Fans